The Shift to Real-Time Control

In an increasingly automated world, industries like eMobility, agriculture, and construction demand precision, efficiency, and adaptability. At the heart of this transformation lies real-time machine control. From its humble beginnings with simple programmable logic controllers (PLCs), this technology has evolved into a sophisticated ecosystem powered by embedded electronics, IoT, and AI.

Real-time machine control isn’t just a technical milestone; it’s the foundation for achieving operational excellence, enabling industries to meet today’s challenges and seize tomorrow’s opportunities.

The Historical Evolution of Machine Control

How Machine Control Began

Machine control began in the 1960s with the introduction of PLCs. These early systems, though groundbreaking at the time, were limited to simple tasks like timing and sequencing. They allowed basic automation by replacing manual processes with programmable digital logic.

The Rise of Real-Time Systems

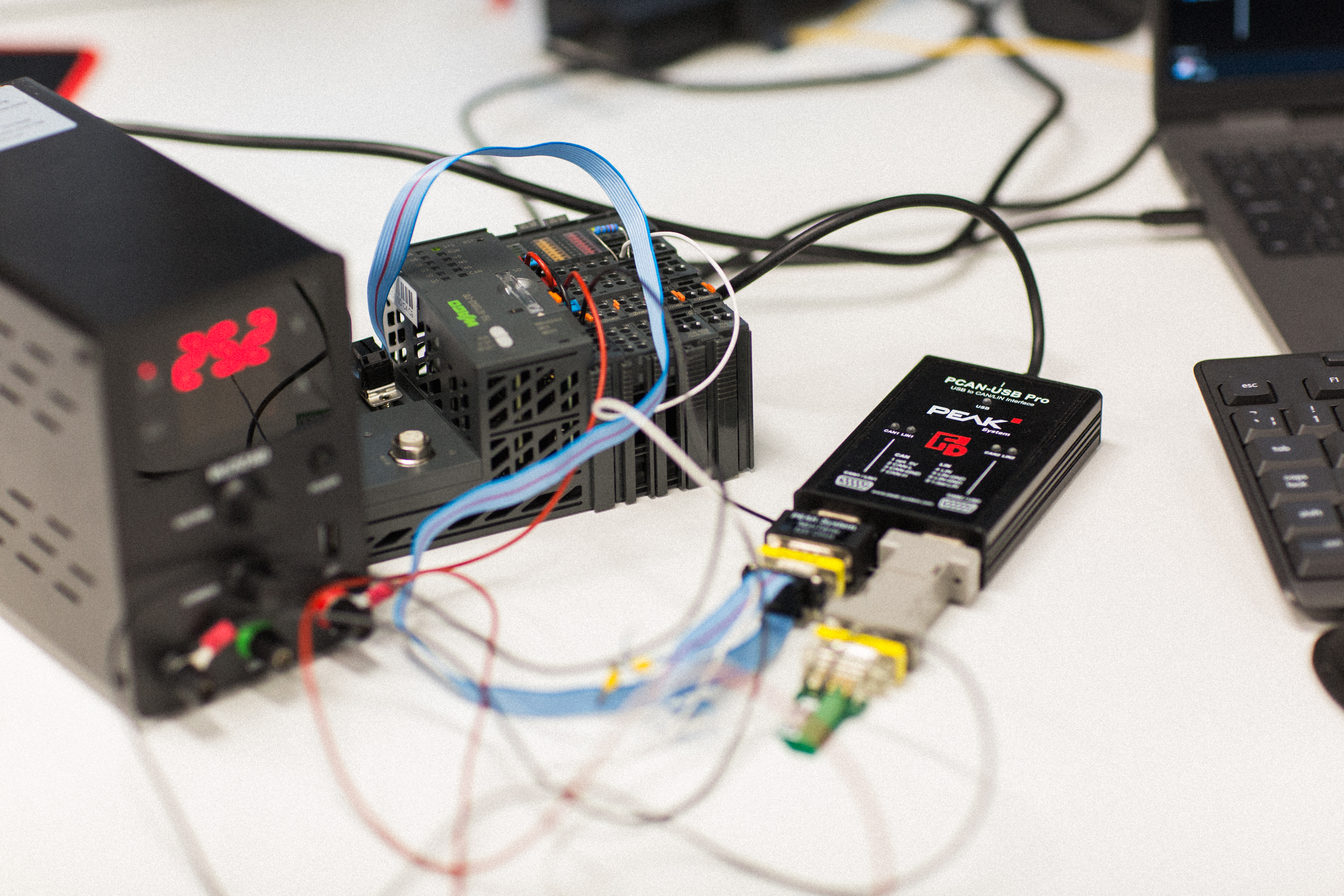

The 1980s saw a revolution with the development of microcontrollers and digital networks like CAN-bus, which allowed machines to communicate and share data in real-time. This breakthrough enabled more complex and coordinated operations, especially in industries requiring high precision, such as automotive manufacturing and industrial automation.

Machine control has advanced, leveraging IoT, AI, and sensors to deliver unparalleled adaptability, efficiency, and scalability.

Current Applications of Real-Time Control in Automation

eMobility

In the eMobility sector, real-time systems optimise energy management, enhance safety, and ensure seamless operation of electric powertrains. These systems are critical for modern electric vehicles, from battery management to advanced driver-assistance systems (ADAS).

Off-Highway Vehicles

Real-time control is indispensable in off-highway agriculture, construction, and mining applications. Precision control systems help reduce fuel consumption, minimise downtime, and improve operational efficiency in demanding environments.

Industrial Automation

Factories and industrial setups rely on real-time systems for predictive maintenance and adaptive manufacturing. These systems monitor real-time equipment performance, enabling proactive decision-making and minimising production disruptions.

Did you know? Modern embedded systems can process data in milliseconds, ensuring machines adapt instantly to changing conditions.

Benefits of Real-Time Machine Control

Real-time machine control offers significant advantages that go beyond automation:

- Efficiency: Faster response times reduce waste and improve productivity.

- Sustainability: Optimised resource usage aligns with environmental goals.

- Reliability: Predictive analytics minimise unexpected breakdowns, enhancing uptime.

- Scalability: Flexible systems adapt to future demands, ensuring long-term ROI.

These benefits make real-time control a cornerstone for industries looking to stay competitive and sustainable in a fast-changing world.

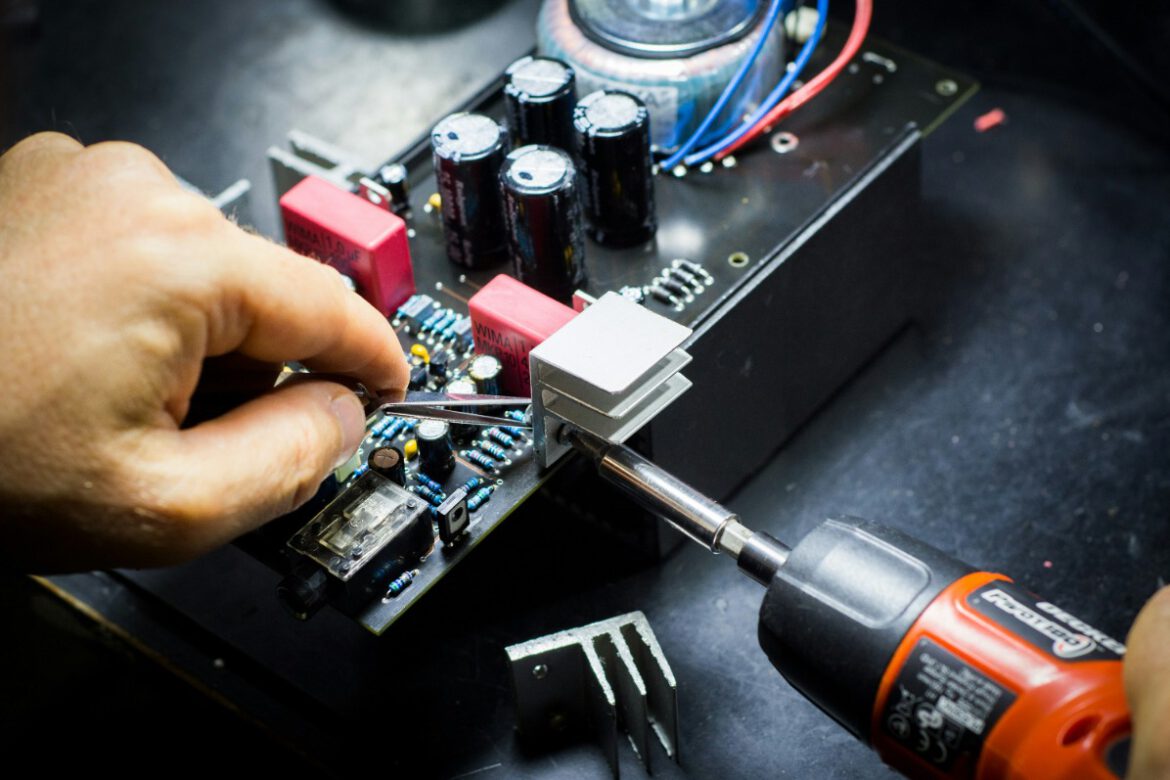

The Role of Control Technologies UK Ltd

For many years, Control Technologies UK Ltd has been delivering cutting-edge real-time control systems. Our expertise spans embedded electronics, system design, and advanced diagnostics, helping clients achieve their goals in eMobility, off-highway, and industrial automation.

We’ve powered electric vehicles, optimised off-highway operations, and reduced emissions for leading manufacturers. Our solutions are designed to meet today’s demands and future-proof operations for years to come.

Looking to enhance your automation capabilities? Contact us to learn how real-time control can transform your operations.

The Future of Real-Time Control in Automation

AI Integration

More innovative systems will increasingly leverage AI to make proactive decisions, improving efficiency and reducing human intervention.

Edge Computing

Decentralised processing will enable faster response times by analysing data closer to the source, minimising latency.

5G Connectivity

The rollout of 5G will unlock real-time data sharing across complex networks, making large-scale automation more feasible and reliable.

Sustainability Focus

As industries strive to reduce carbon footprints, real-time control systems will be critical in optimising resource usage and energy efficiency.

The future of real-time control is bright, and the possibilities are limitless. Control Technologies UK Ltd is proud to be a part of this journey, shaping the future of automation with innovative and reliable solutions.

Conclusion

Real-time machine control has come a long way, from basic automation to the intelligent, adaptive systems we rely on today. At Control Technologies UK Ltd, we’re proud to play a key role in shaping this future. As industries embrace automation, the possibilities for efficiency, sustainability, and innovation are boundless.

Looking for expert guidance in real-time control systems? Explore our services and discover how we can support your business.