Overview

Control Technologies was engaged to support the development of a next-generation agricultural planting system using a distributed CAN and CAN FD control architecture. Before physical machines were assembled, the customer needed confidence that complex communication, timing, and control logic would operate reliably in the field.

Our role was to design and implement a laboratory-based test bench that could simulate the complete machine network, allowing early validation, faster debugging, and reduced integration risk.

The challenge

Modern agricultural planting systems rely on multiple electronic control units (ECUs), sensors, and actuators working together in precise, deterministic ways. These modules communicate over CAN and CAN FD networks and must maintain strict timing, message integrity, and predictable bus loads to ensure accurate planting operations.

For this project, the customer was developing a new modular planter platform with:

- Distributed control units across the machine

- Mixed CAN and CAN FD communication

- Complex I/O behaviour

- Safety-critical diagnostics and error handling

Traditionally, many of these issues only become visible during late-stage integration or field testing. This increases development time, raises costs, and introduces significant risk if communication faults appear once physical machines are already built.

The customer needed a way to:

- Simulate the full machine network in a controlled environment

- Validate CAN and CAN FD communication early

- Test message timing, bus load, and ECU interaction

- Inject realistic sensor signals before hardware integration

Our approach

Control Technologies designed and built a comprehensive CAN FD test bench environment that allowed the entire planter network to be simulated from a development PC.

The goal was to create a repeatable setup that engineers could use daily to analyse communication behaviour, debug software, and validate control logic long before field deployment.

Key requirements included:

- Real-time monitoring of CAN and CAN FD traffic

- Simulation of sensor inputs such as voltages, temperatures, and currents

- Logging and visualisation of network behaviour

- Support for both Classical CAN and CAN FD

- Flexibility to adapt as the system evolved

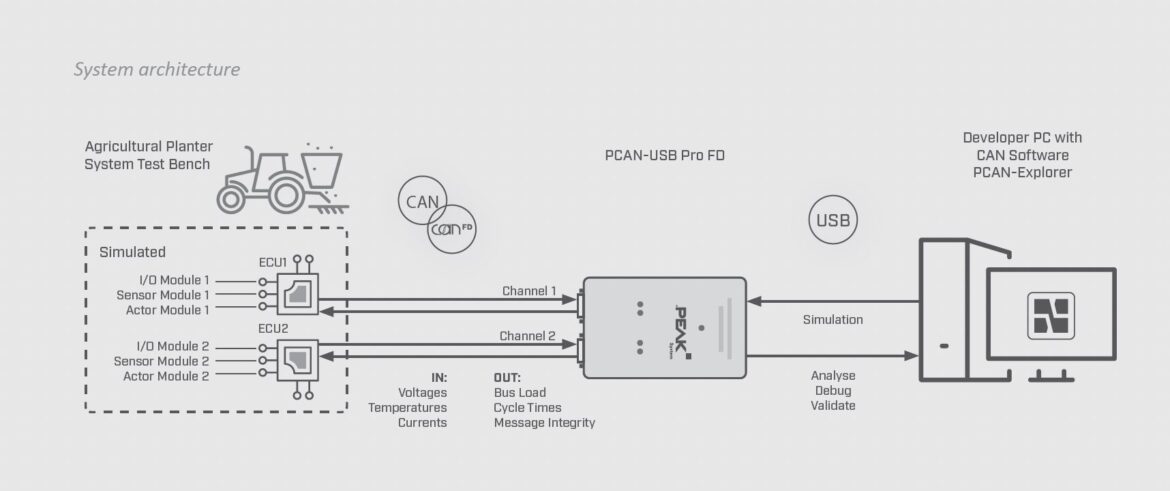

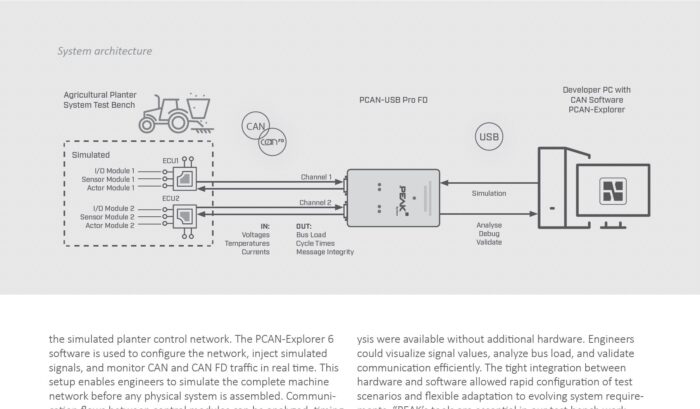

Test bench architecture

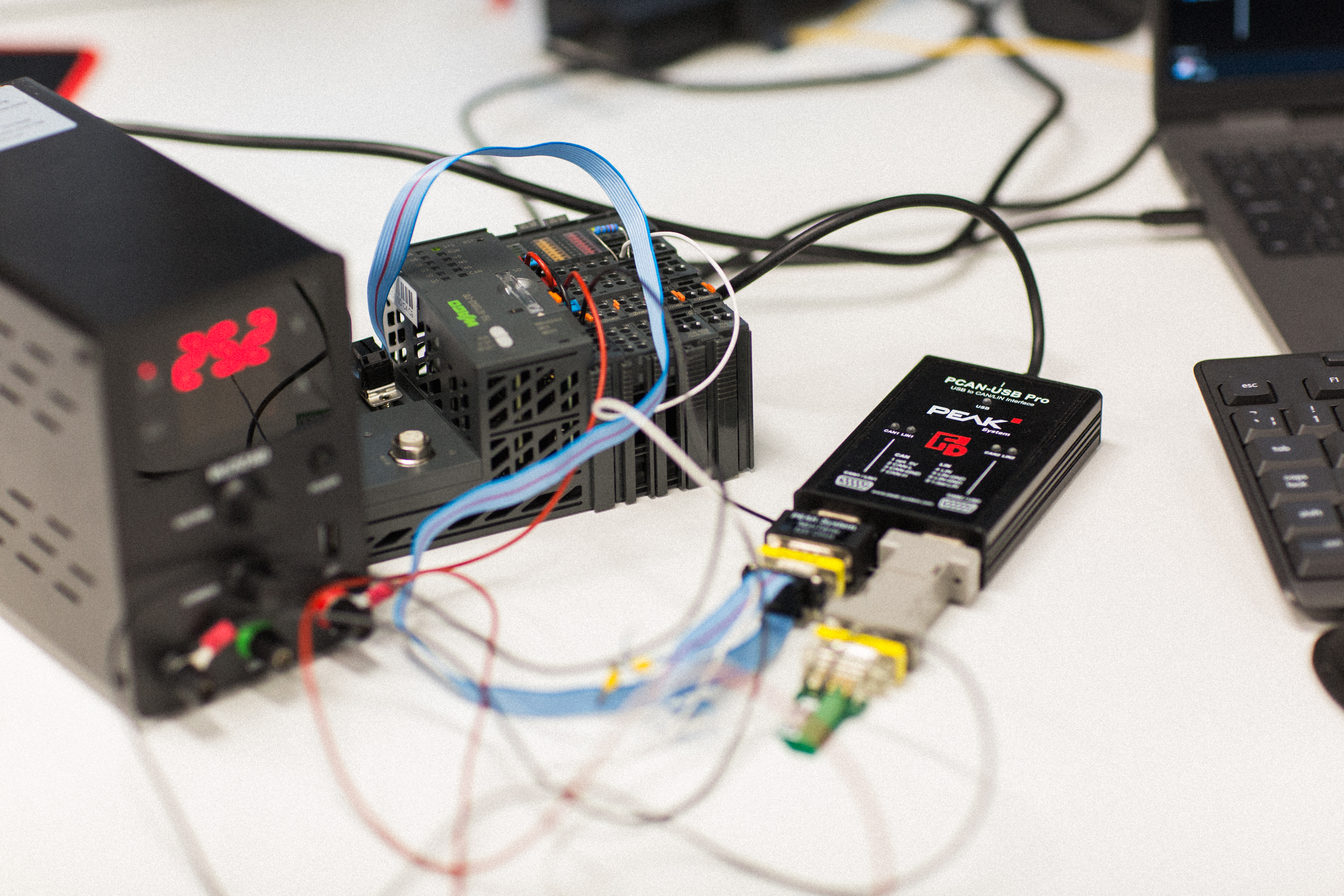

The test bench was built around PEAK-System CAN hardware and analysis software, specified and implemented by Control Technologies.

Watch the test bench walkthrough

In this short video, we walk through the CAN FD test bench setup and explain how the system is used for simulation, analysis, and validation.

At the centre of the setup was the PCAN-USB Pro FD, providing two independent CAN FD channels between the development PC and the simulated planter control network.

Using PCAN-Explorer 6, engineers were able to:

- Configure the complete CAN and CAN FD network

- Monitor live traffic in real time

- Analyse bus load, cycle times, and message integrity

- Log communication for offline review

- Transmit simulated messages and sensor values

This closed-loop setup allowed both observation and active interaction with the system. Control modules could be tested under realistic operating conditions without requiring a fully assembled machine.

The dual-channel CAN FD capability was particularly important, enabling parallel network analysis while maintaining compatibility with legacy CAN devices used within the system.

Results and outcomes

By validating the communication architecture at an early stage, the test bench delivered measurable benefits throughout development:

- Early validation of complete CAN and CAN FD machine networks

- Faster identification of communication and timing issues

- Reduced reliance on late-stage field testing

- Shorter commissioning time once physical systems were built

- Improved overall system reliability

Engineers were able to iterate quickly, reproduce issues consistently, and validate fixes under controlled conditions — significantly reducing development risk.

As the system evolved, the test bench could be easily adapted to support new modules, software updates, and changing requirements.

Partner collaboration with PEAK

This project was delivered in close collaboration with PEAK-System, using their CAN interfaces and analysis tools as the foundation of the test environment.

The tight integration between PCAN hardware and PCAN-Explorer software enabled rapid setup, clear visualisation, and efficient debugging, without the need for additional specialist hardware.

As Rob Carlaw, Digital Sales & Marketing Manager at Control Technologies, explains:

“PEAK’s tools are essential in our test bench work. They give us reliable CAN communication and make it easy to analyse and debug complex machine networks. These products have become part of our engineering team’s day-to-day workflow.”

Why this matters for machine builders

For OEMs and machine builders working with increasingly complex electronic architectures, early validation is critical.

A well-designed CAN FD test bench allows teams to:

- Reduce integration risk

- Improve software quality

- Shorten development timelines

- Minimise costly rework during commissioning

By simulating complete machine networks before physical assembly, engineering teams gain confidence that systems will perform as intended when deployed in the field.

Want to learn more?

If you’re developing or upgrading CAN or CAN FD-based systems and want to explore test bench simulation, validation, or integration support, Control Technologies can help.

👉 Download the full technical case study (PDF) below for a deeper dive into the system architecture and communication setup.